I'm getting a little tired of making the same points over and over again. If there is nothing really new added to this conversation I won't be back here to pull things apart. Your latest comment is filled with so many holes. The problem is, they take a lot of time to explain. I don't have that time right now. I will give it my best real quick here.

Originally Posted by

UNISATPS is fine buddy, trust meYou said TPS data was inconsistent and to ignore it. It also looks completely fucked from your logs. Is it fine, or is it fucked? It can't be both.

Originally Posted by

UNISAhonestly you should hook up a MAP sensor and log with it a whileHonestly you should read my posts a little closer and do try to remember you're talking to the same person who said this earlier:

Originally Posted by

BenFenner

Originally Posted by

UNISAARE ANY OF YOU LOGGING WITH A MAP SENSOR? ANY OF YOU? DIDNT THINK SO OR ELSE YOU ALL WOULD BE TELLING ME NO SHIT!

However, I have no way to log TP, otherwise I'd have the graphs posted already.

Pro Tip: You can tell me from everyone else on the forum based on my username, and avatar.

Originally Posted by

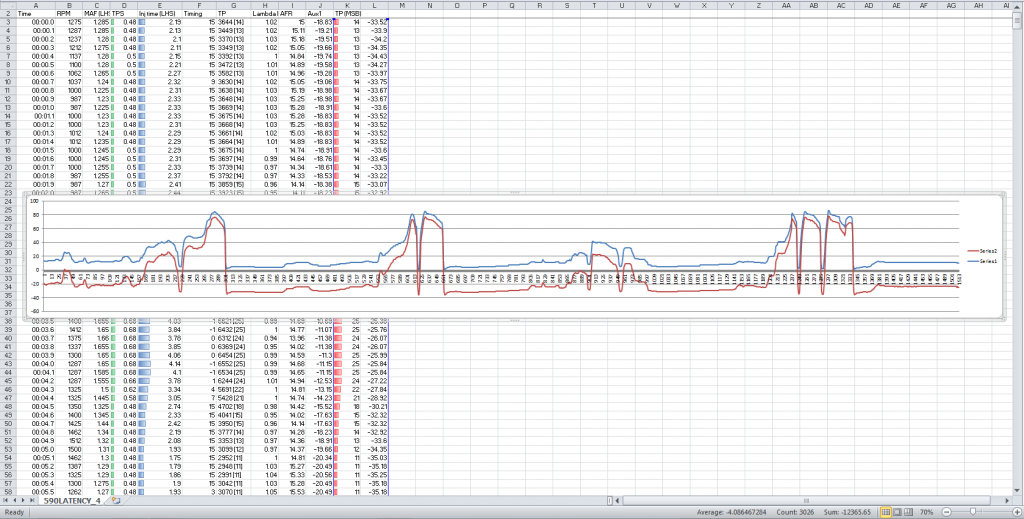

UNISAand you would see how it correlates to TP on a daily basis, its not off in that huge range your giving it,That is not true. TP does not correlate with pressure, and it is off in that huge range I'm giving it. Dave's scatter plot is quite good at showing how fucking huge the swings are in TP in relation to pressure. Those aren't all just stray data points. They describe a huge island where TP and pressure can swing around by 50+% independent of each other.

I completely understand why you think they are so closely linked, because of all these logs you're posting. It seems very convincing. Your problem is that your engine doesn't rev high enough, and/or won't keep a steady pressure long enough to show the difference. And again, it is not a tiny thing.

Originally Posted by

UNISAif that where the case that stock ECU would have to modiify the TP colums on the fly so that it accessed the right parts of the maps and that it does not do.No. For fuck's sake no. Jesus Christ, this is not a fucking speed density setup. Get that through your thick skull. The ECU doesn't have to do any such thing. If the designers wanted pressure, they'd put in a damn pressure sensor. The designers don't give a shit about pressure, and neither should you. You have a MAF sensor, and it literally reads incoming air molecules. With the known 20% oxygen content of air in the Troposphere you can get an exact measurement of the mass of oxygen molecules entering the intake at any time. Take that data and divide it by the current engine RPM and you now know how much torque the engine should be making. Take that and divide it by the number of cylinders, and you have an estimation for how much fuel is needed for a single cylinder. Do a one-time scaling for your choice of injector and you're HOME FREE! No need to ever ever ever ever know anything about pressure.

For the record, the best guess we have for the TP formula is this:

TP = (VQ · K value / CAS value) / Number of cylinders

VQ comes from the MAF look-up table and CAS is the Cam Angle Sensor reported RPM divided by 50 then multiplied by 256.

Supposedly it is not perfect, but it is damn close plus or minus other trim factors.

Reference:

http://www.ztechz.net/id10.html

How on God's green Earth you figure TP has anything to do with pressure is beyond me. It really is. You also don't seem to get the concept that it is perfectly possible to control an engine without ever having even the faintest concept of what pressure is. STOP THINKING ABOUT SPEED DENSITY FOR ONE SECOND and work with a clean slate.

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top