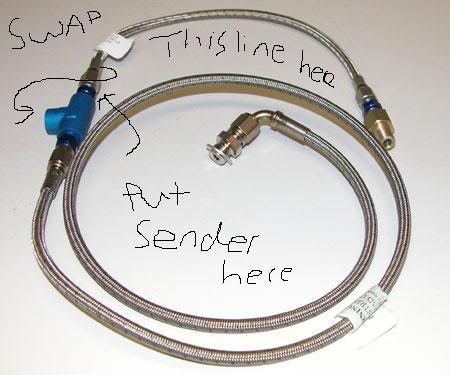

So, I've had my motor sitting for about a year now since I rebuilt it. Its read low oil pressure since I first cranked it, and I havnt really run it for more then a few mins at a time since. I finnaly got some free time to look into it, and I'm beginning to think its the GFD oil feed line I'm using making my inline gauge read low. On cold start it reads about 37-40psi, and drops to less then 10 psi when warm at idle (but the stock oil warning light never comes on...)

I've tried 2 different gauges (one mech, one electronic) and I have a brand new oil pan installed, so I'm 100% positive its not dented.

Has anyone else ran into similar issues w/ their GFD oil pressure line?

I've tried 2 different gauges (one mech, one electronic) and I have a brand new oil pan installed, so I'm 100% positive its not dented.

Has anyone else ran into similar issues w/ their GFD oil pressure line?

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top