This is a renovation and continuation of a post first made by me on another SR20 Forum.

Initial Assessment

After more than a year of collecting dust, my Calum daughterboard ECU is now actually IN the car. I drove for a week with the Innovate! AFR as my copilot to assess the fuel mixture and general behavior of the ECU. I am using Calum's SR20DE tune version 4 on my 1991 Classic with AEM CAI, TopSpeed Header and fuel pressure set a 44 psi (with the vacuum hose removed and plugged).

Here is what I have found:

1. The car drives well -- no roughness (after I changed timing from 19*BTDC to 15* BTDC and opened the IAV screw by a quarter turn to restore the idle).

2. The car feels peppier -- pulls nice from mid to high RPM. Can't wait to get it on the dyno.

3. Idle AFR is rich -- 12.5 after full warm up.

4. WOT AFR is rich -- 12.5 on a long pull in 3rd, drifting up toward 12.7 at 7000RPM.

5. Light throttle AFR is rich -- 13.5 at steady speed

6. The car still got 33 MPG in mixed driving even though it is running a little rich.

I do not think that the feedback loop is working to maintain 14.7 at idle and light throttle.

I ran an Active Test with Nissan DataScan with the fuel delivery cut to 90% of what the ECU was trying to deliver. This accomplished the following:

1. Idle AFR increased from 12.5 to 14

2. WOT AFR increase from 12.5 to 13.5-13.7

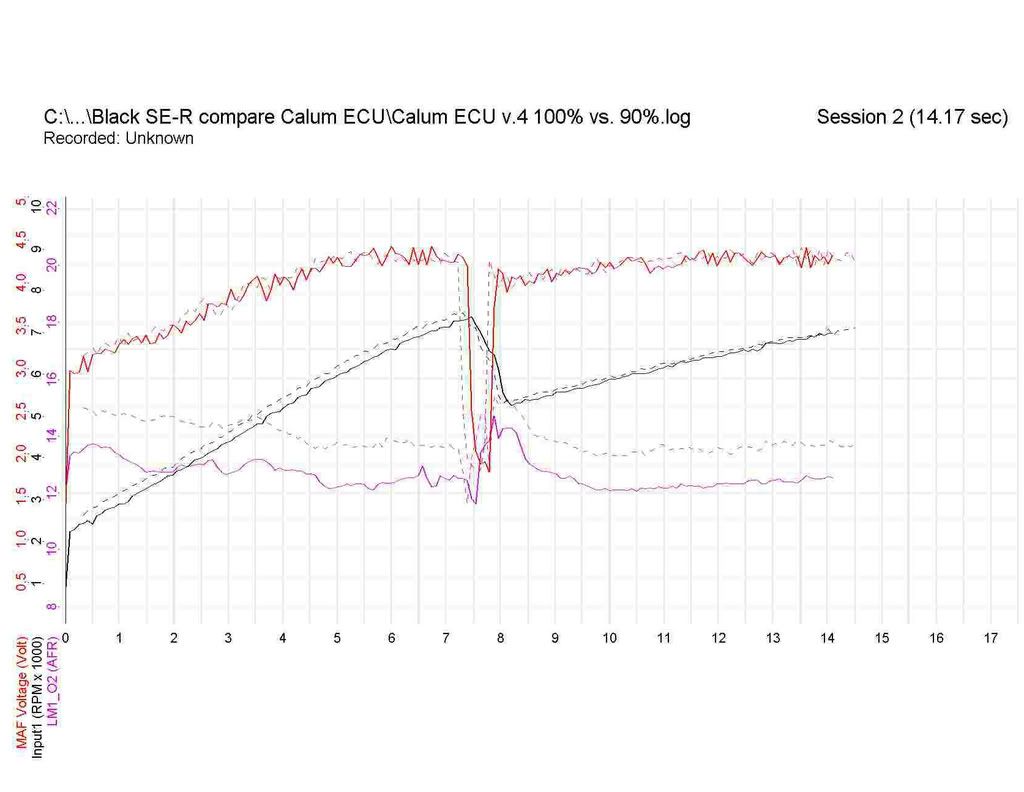

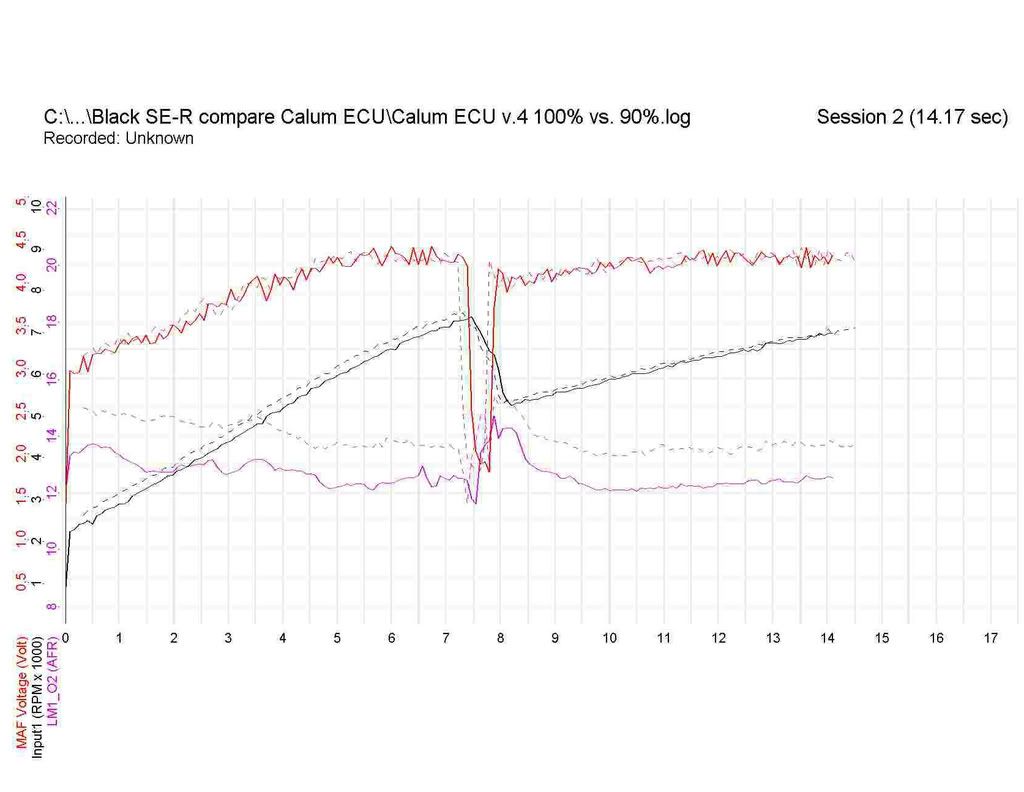

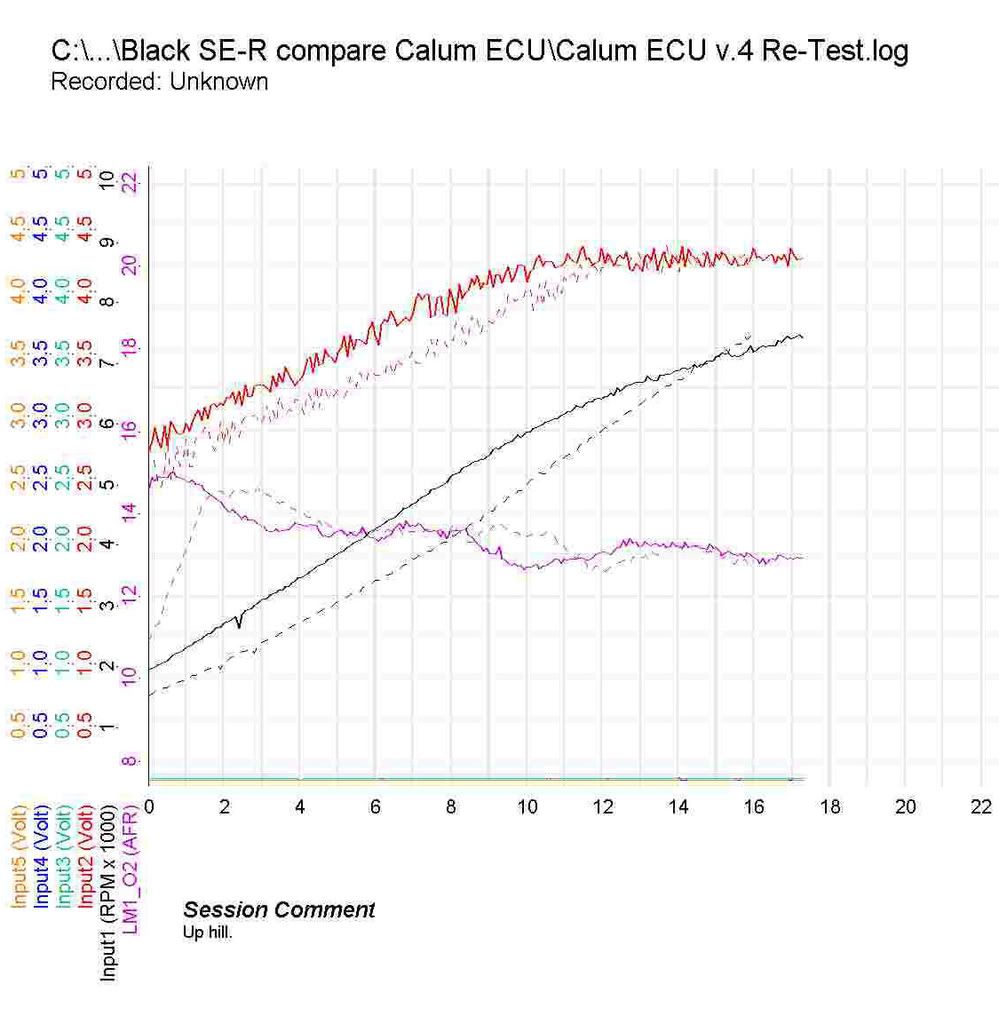

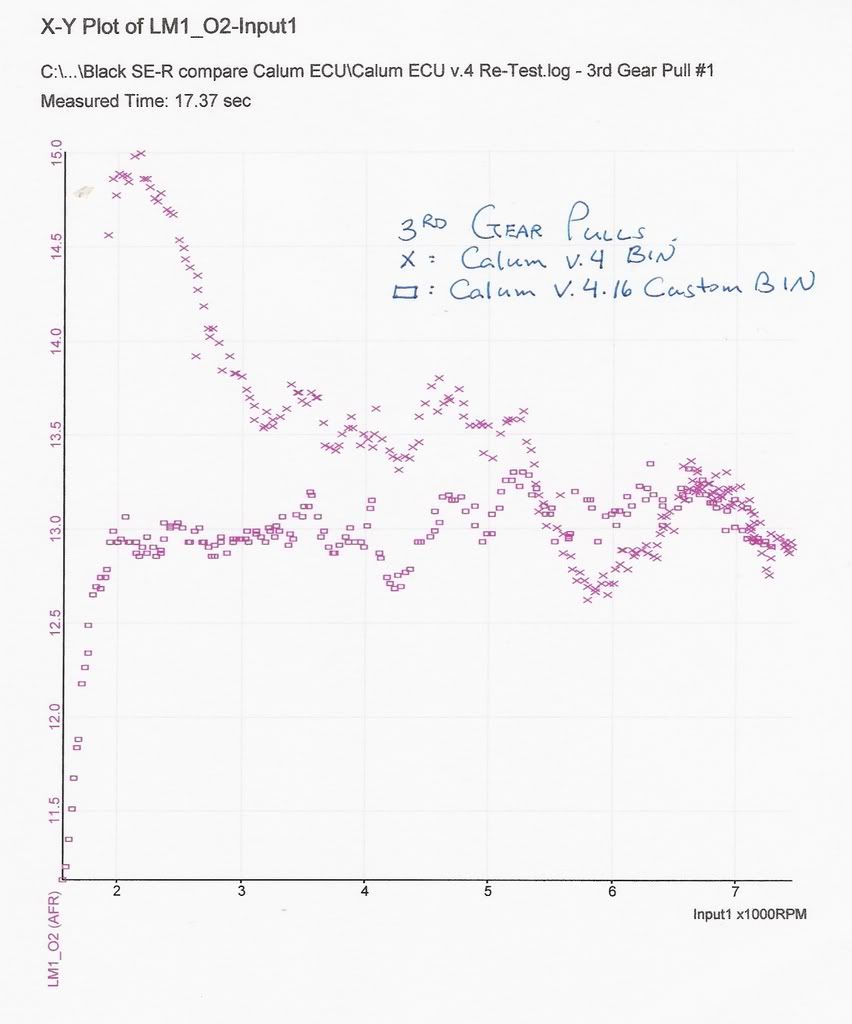

Here is a display of data collected by the Innovate LM-1 during a run through 2nd and 3rd gears. The dashed lines show the test with 90% fuel delivery using Nissan DataScan active test, the solid lines are 100% fuel delivery. Black lines are RPM, purple are AFR, and the red is MAF voltage, all plotted against seconds.

How should I proceed?

Should I reduce the K value by about 15% to try and adjust the idle mixture to 14.7? This will make other areas of the fuel map too lean and so then I would have to go back and increase individual cells.

OR

Should I reduce the K value (about 7%) to tune in the WOT AFR to 13.3-13.5 and live with the idle?

OR

Should I try some other approach like adjusting the individual values in the fuel map?

I'm new to this stuff, so any suggestions are welcome.

Bill

Initial Assessment

After more than a year of collecting dust, my Calum daughterboard ECU is now actually IN the car. I drove for a week with the Innovate! AFR as my copilot to assess the fuel mixture and general behavior of the ECU. I am using Calum's SR20DE tune version 4 on my 1991 Classic with AEM CAI, TopSpeed Header and fuel pressure set a 44 psi (with the vacuum hose removed and plugged).

Here is what I have found:

1. The car drives well -- no roughness (after I changed timing from 19*BTDC to 15* BTDC and opened the IAV screw by a quarter turn to restore the idle).

2. The car feels peppier -- pulls nice from mid to high RPM. Can't wait to get it on the dyno.

3. Idle AFR is rich -- 12.5 after full warm up.

4. WOT AFR is rich -- 12.5 on a long pull in 3rd, drifting up toward 12.7 at 7000RPM.

5. Light throttle AFR is rich -- 13.5 at steady speed

6. The car still got 33 MPG in mixed driving even though it is running a little rich.

I do not think that the feedback loop is working to maintain 14.7 at idle and light throttle.

I ran an Active Test with Nissan DataScan with the fuel delivery cut to 90% of what the ECU was trying to deliver. This accomplished the following:

1. Idle AFR increased from 12.5 to 14

2. WOT AFR increase from 12.5 to 13.5-13.7

Here is a display of data collected by the Innovate LM-1 during a run through 2nd and 3rd gears. The dashed lines show the test with 90% fuel delivery using Nissan DataScan active test, the solid lines are 100% fuel delivery. Black lines are RPM, purple are AFR, and the red is MAF voltage, all plotted against seconds.

How should I proceed?

Should I reduce the K value by about 15% to try and adjust the idle mixture to 14.7? This will make other areas of the fuel map too lean and so then I would have to go back and increase individual cells.

OR

Should I reduce the K value (about 7%) to tune in the WOT AFR to 13.3-13.5 and live with the idle?

OR

Should I try some other approach like adjusting the individual values in the fuel map?

I'm new to this stuff, so any suggestions are welcome.

Bill

Be the first to like this post.

Be the first to like this post.

Back to top

Back to top